For inspection of the surface condition of the adhesive surface.

10 times the sensitivity of conventional products.

Surface Modification Sensor Caisits,

It is used for determining the level of surface modification

such as plasma treatment, corona treatment and flame treatment .

※ The product name was changed from Luminus to Caisits in July 2018.

◆ Necessity of surface modification treatment

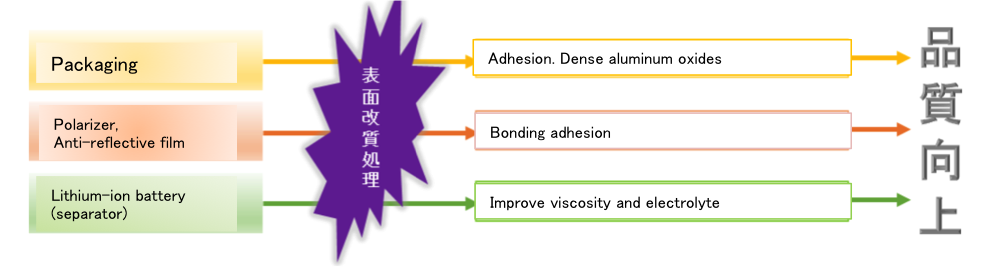

Polymer functional plastic films are widely used not only in packaging applications and general applications, but also in industrial fields such as high-performance products for instance information equipment. in recent years the film has been printed for design purposes, such as the interior of the car and the wood grain.

For example, film for packaging is pretreated on the film so that printing can be successfully printed. In addition, polarizing plates, anti-reflection films, etc. used for displays such as liquid crystal TVs are multi-layered films, and each film is subjected to electrical treatment such as plasma treatment or corona treatment to activate the surface and bond. We are trying to homogenize the product.

Non-contact, nondestructive measurement

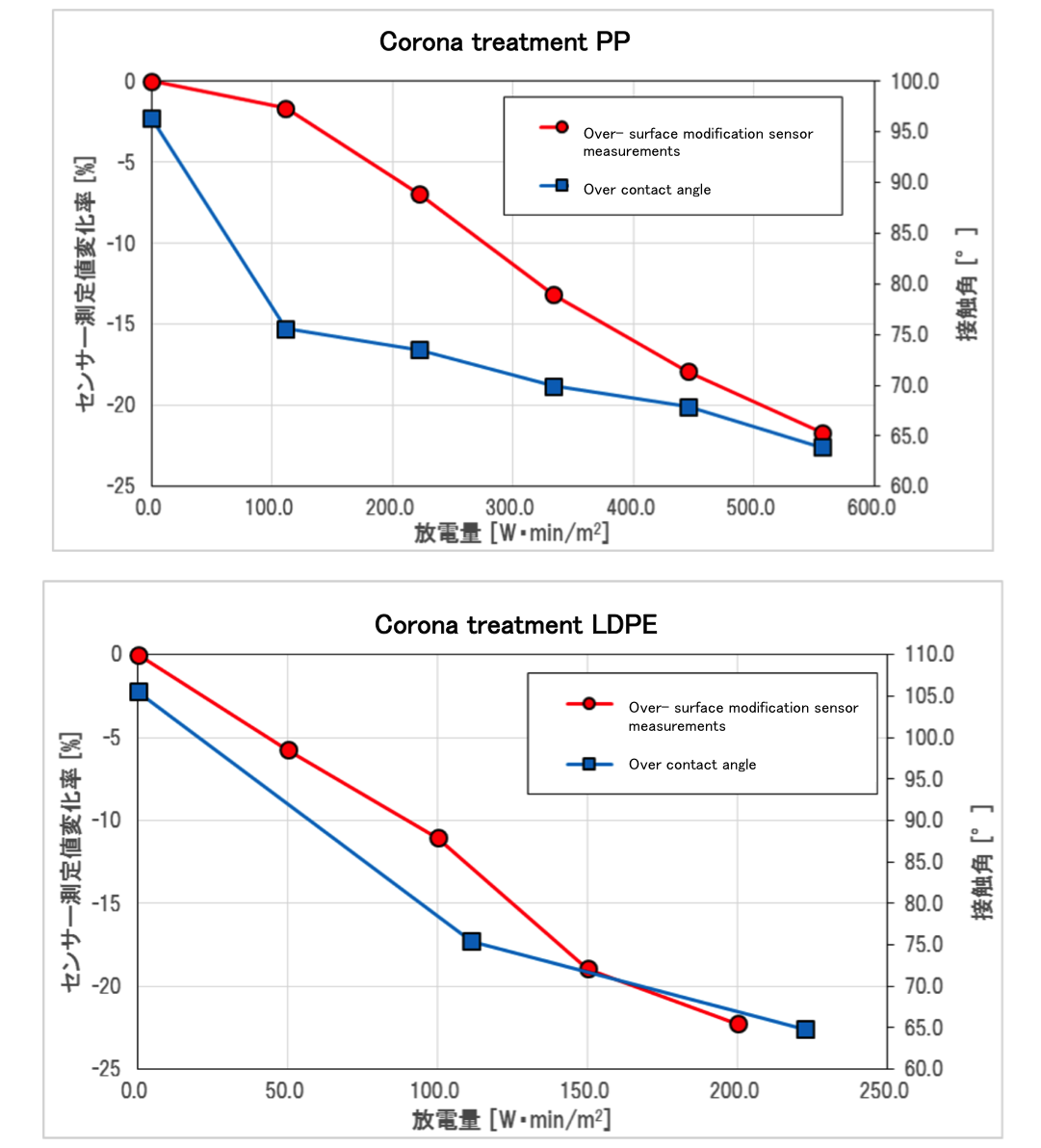

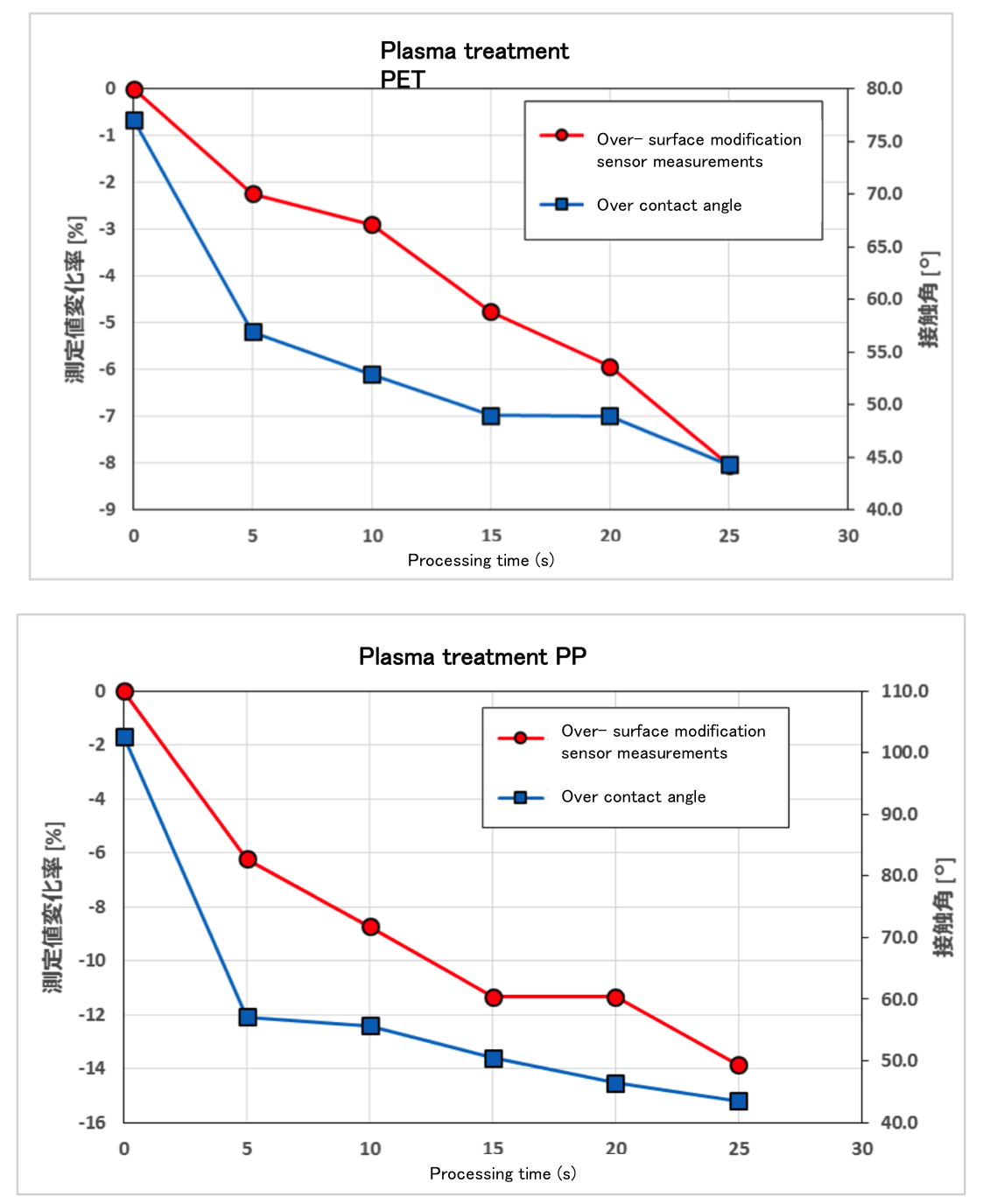

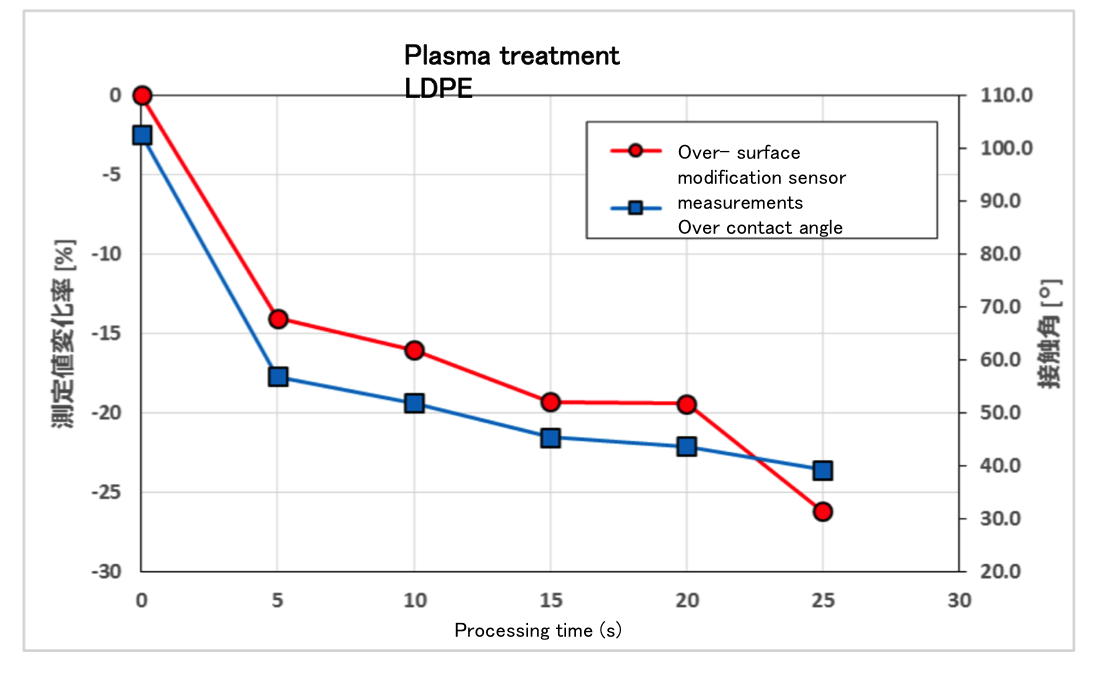

Nondestructive inspection is possible because measurements can be made without touching the sample. The measurement sensitivity is 10 times the conventional one. A full model change is realized, and differences between plasma and corona treatment before and after treatment can be more clearly identified.

◆ Measurement principle

When the surface of a substance that has been surface-modified by plasma or corona treatment is irradiated with ultraviolet light, fluorescence is emitted from that surface. By measuring the amount of emitted fluorescence, it is possible to measure quantitatively the presence / absence of modification.

◆ Wide applications

In recent years, it has been found that it is effective not only for inspection after surface modification processing such as plasma processing and corona treatment, but also for inspection of soiling of electronic substrates etc., detection of oil on the surface, and other inspection during cleaning. Furthermore, recently, much attention has been focused on surface condition inspection in each process related to weight reduction of automobiles.

◆ Regular

◆ Please try your sample first

At AcroEdge you can feel free to try Caisits for sample measurement and demonstration trials. Please check with your eyes to visualize the degree of surface modification after surface treatment. In addition, customers who are in need of evaluation of surface condition such as “dirt” and “peeling”, please contact Acroedge.

◆ Caisits Optional Products “Standard fluorescent substance“

Acroedge has started selling standard fluorescent materials and options for surface modified sensor “Caisits”.

This is a standard substance used for performance inspection at the time of shipment.

If you have a standard fluorescent substance, you can check at your preferred time whether it is within the tolerance of the sensor’s measurement reference value. It also leads to the early detection of equipment abnormalities, enabling high quality control to be maintained. Please feel free to contact us.